This is an ongoing series of blog posts that will showcase the design, construction and installation of a decorative steel veranda railing for our Benjamin Street project. To read the previous post in this series, click the link here or go to the main blog page.

So we have our design; we have all of our original and necessary new pieces; we have our equipment ready. Now it’s time to begin the deconstruction of the segments we are repurposing in coordination with our design plans.

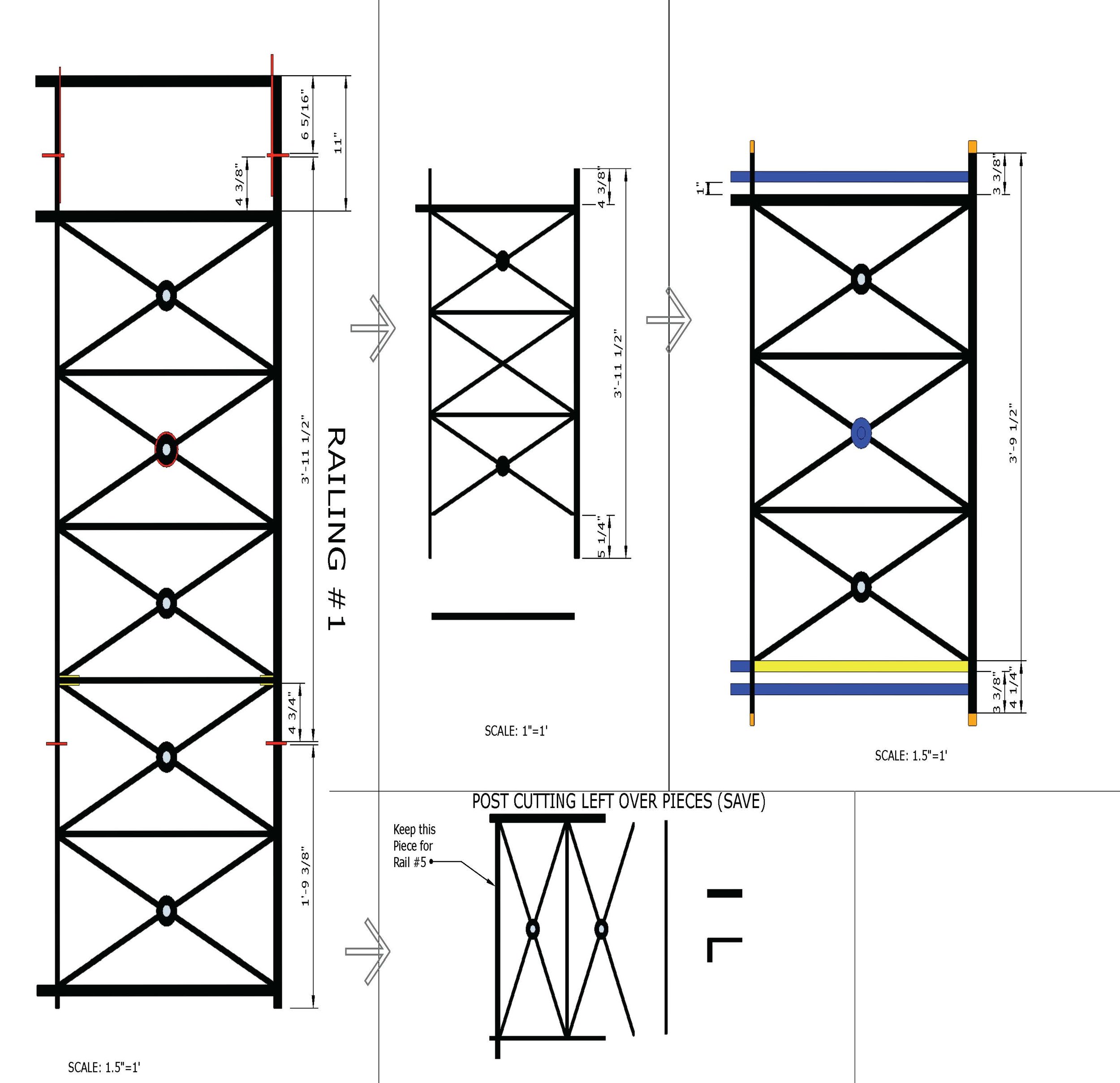

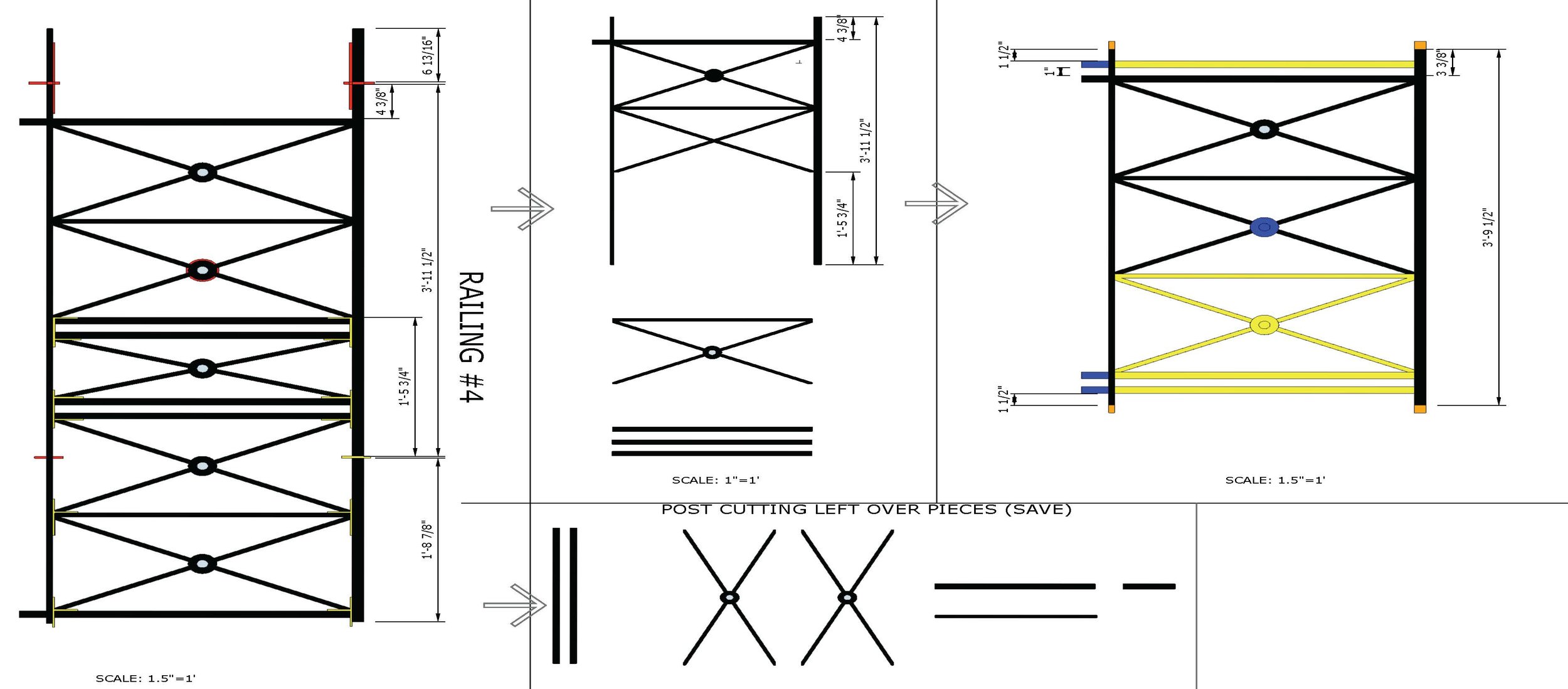

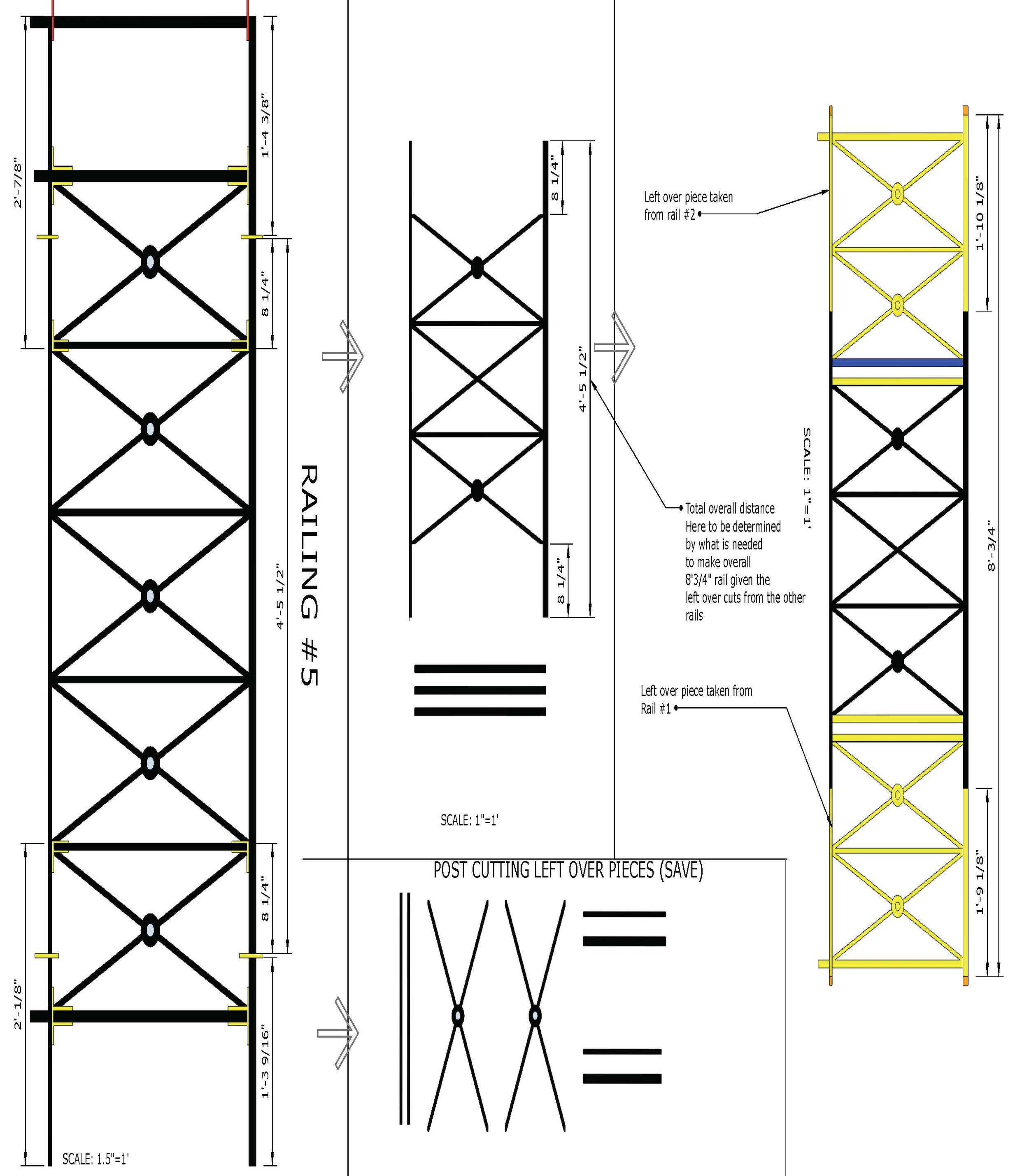

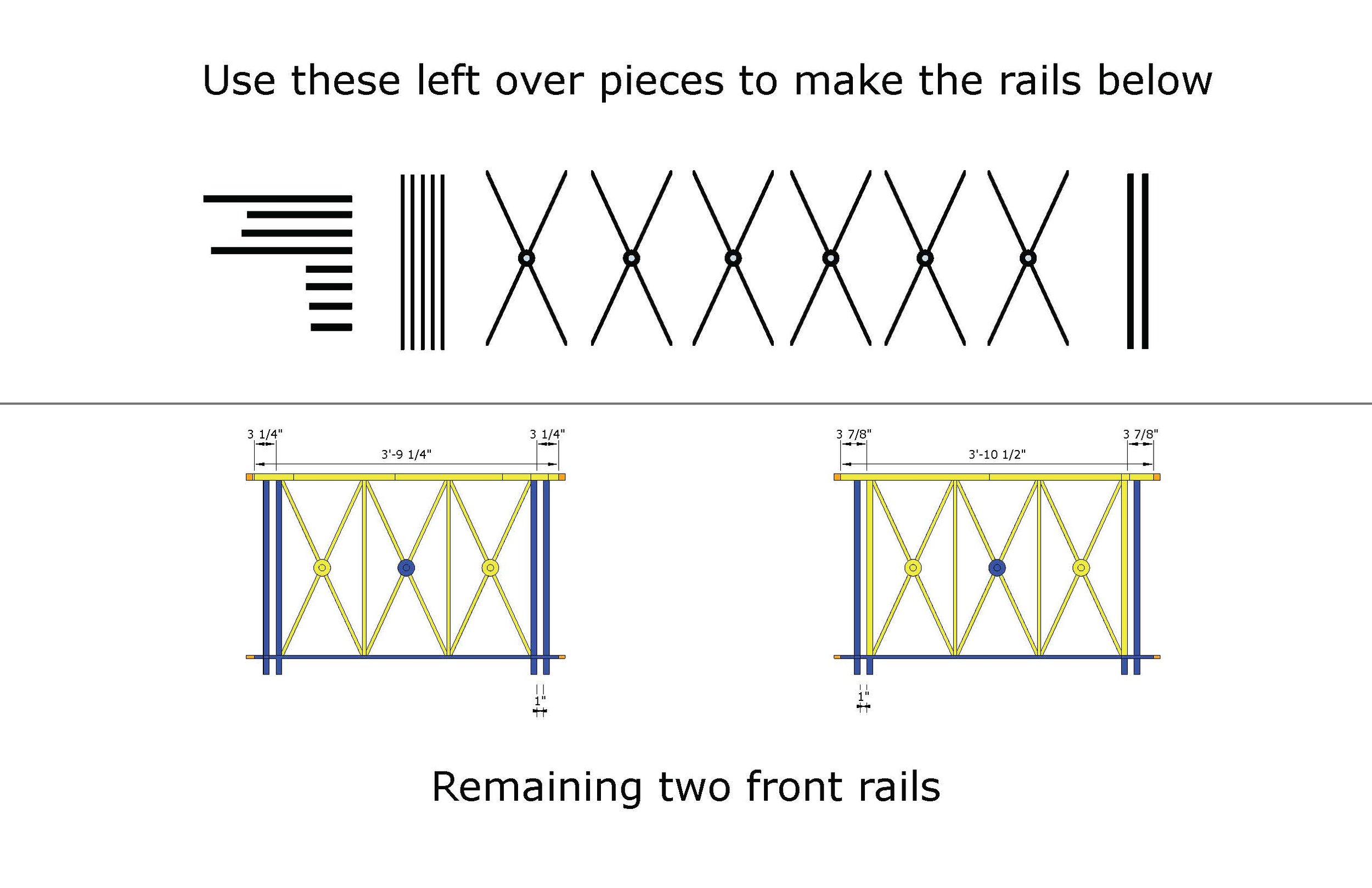

We showed you our intentions as to what pieces needed to be removed as we cut the rail into smaller sections and now it’s time to test the preliminary big segment cuts. For example, look at layout for ‘Railing #3’ and its different color-coded pieces.

These indicate a variety of things: the red lines indicate the initial cuts needed on the existing pieces; the yellow color indicates that a specific piece removed from another section will be inserted in that given location and the blue color means an insertion of a new piece of steel that we ordered and had on hand to replicate the missing necessary features.

On Railing #3 we needed one 1” square vertical bar from another rail as well several pieces from our pile of new steel. The new pieces needed were two 1” square vertical rails, three 1” square footer pieces and two decorative rosettes that we would weld on each side, replacing the previous rosettes that were no longer on the center-most rail section.

The new rosettes we found were from King Architectural Metals and fit our ideal size as well as a similar aesthetic to the old ones. It had an open hole in the center, which would allow us to weld it down properly, overtop of the previous center spoke from which we had removed the original rosette.

Each rail segment followed the same procedures based on our design. Using a Sawzall reciprocating saw with a specific steel cutting blade, the dismantling began and segments became lighter and more in-line with the end product.

Once a given segment had been cut at the red cut points and the removed pieces were set aside, they were laid out on the back deck of our workshop. One by one, the segments were cut down and our pile of leftover parts grew. You can see the progress in the pictures that show the rails prior to any additions.

Each section was meticulously labeled to ensure that each section was true to size based on our original measurements we took from the veranda and the placement of the dividing posts. When all seven rail segments were completely cut down, it was time to divide up pieces from the extra pile.

The next step before welding the existing pieces down was to cut the remaining bars needed from our pile of new steel. We cut the steel based on our overall layout design, leaving a little extra on the ends since cutting the steel a little too long is better than cutting it too short.

Once we had all the necessary bars and rails cut to size, we started tack welding the pieces in place. Tack welding is the process of using small weld points to keep something in the proper location and alignment before final welding can be completed to truly lock the steel in place.

Once a segment had all of its pieces in place, I went around all the seams and gave it a solid final weld.

After the segment had cooled down from the welding, each one had to be grinded and smoothed down using an electric hand grinder with a special metal cutting disc to remove any steel splatter and rough welds.

The final items to be welded were the aforementioned decorative rosettes. They are made of a very thin bit of steel, making them very delicate to weld down without melting them, which is why I saved them for last.

Now that all of the welding on a given section was complete, it was time to give them a few coats of black Rustoleum exterior paint to lock the steel away from moisture and possible future rusting. This entire process was done for each segment: cutting, dividing, adding, welding and painting.

All seven segments followed this process in a lengthy and somewhat aggravating process. By the time the segments were completed, I had earned several minor scars from burns and an achy back from moving these heavy steel rails.

While the whole progression of the rails was tedious, seeing each of the final products leaned against the wall ready for installation was extremely gratifying.

Check back for the final post in this series to see how the rails turned out once we began the installation process on the porch veranda roof.